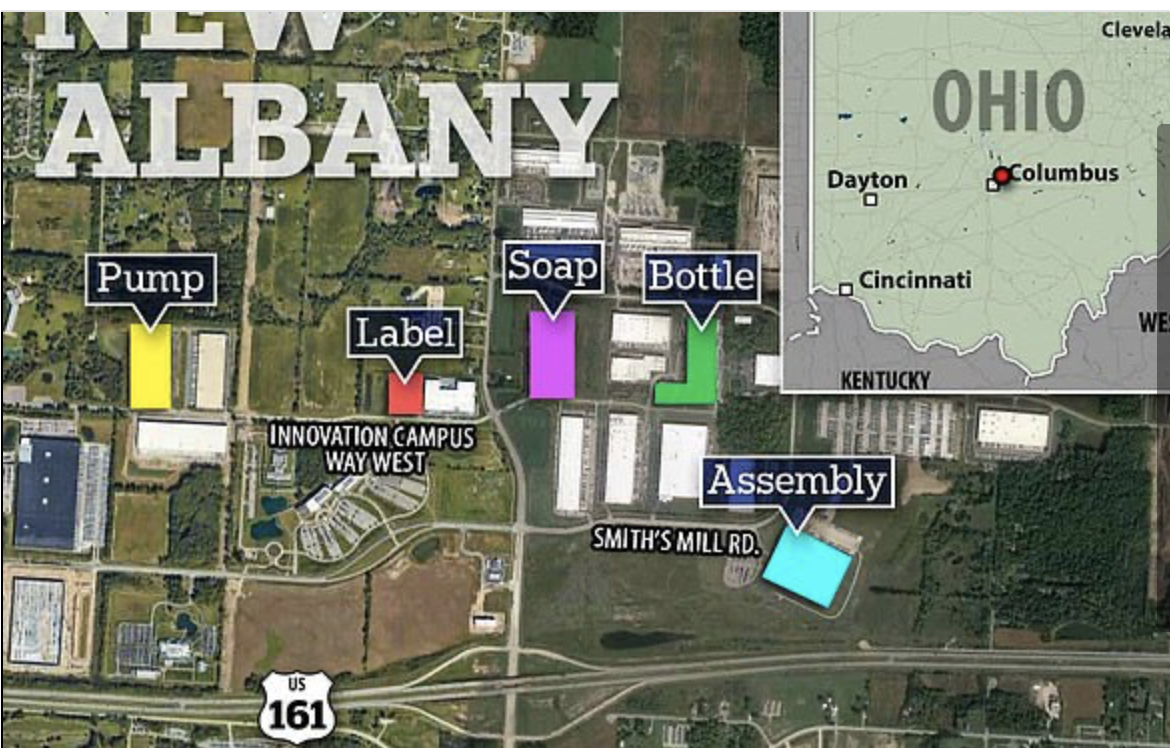

NEW ALBANY, Ohio—A $7.95 bottle of Bath & Body Works foaming hand soap used to take three months to put together. The pieces had to travel more than 13,000 miles from China, Canada and Virginia to the company’s Ohio distribution center.

Bath & Body Works shifts almost all production from China to Ohio – and revenue has soared

- Bath & Body Works manufactures components for almost all its products in Ohio

- It can deploy an entirely new product in just 21 days – down from five months

- Domesticating supply chains or ‘reshoring’ is growing in popularity in the US

Soap and fragrance retailer Bath & Body Works (BBW) has shifted the international supply chain it needed to make its most of its products to a single campus in Ohio.

Originally the pump for a bottle of hand soap came from China, the bottle itself from Canada, the label from New Jersey and the soap itself from Virginia. But now, every component is manufactured within a several million square foot ‘beauty park’ in the outskirts of Columbus.

The new system rapidly decreased the time it takes them to deploy an entirely new product from more than five months to just 21 days. It’s net sales were $7.6billion last year, an increase of more than $2.2billion since 2019.

Bath & Body Works’ move to localize and domesticate the majority of its supply chains is part of a wider trend of increasing interest to Wall Street executives, known as ‘reshoring’. Much more at Daily Mail.

Some companies get it. The supply chain is compromised if it involves China and its imminent invasion of Taiwan. Pressure foe ESG corporate governance is growing – and this act reduces the co-called carbon footprint of the products produced by BBW – and therefore makes you attractive to institutional investors obsessed with the “Climate change is manmade” crowd.

Made in America: Bath & Body Works Shifts Almost All Production from China to Ohio Plant in Latest “Reshoring” Effort https://t.co/XhPpGIJdr9

— The Gateway Pundit (@gatewaypundit) July 29, 2023