A farm replacing a data center in Northern Virginia — is that even possible?

This reversal of development trends happened in September, when Beanstalk Farms, opened at what was an abandoned data center in downtown Herndon.

Beanstalk is no ordinary farm. Named after the “Jack and the Beanstalk” fairy tale the siblings’ mother read to them as children, it uses a new method of high-density, highly automated indoor agriculture that yields hyper-fresh, nutritious produce that can be delivered within 24 hours of harvest.

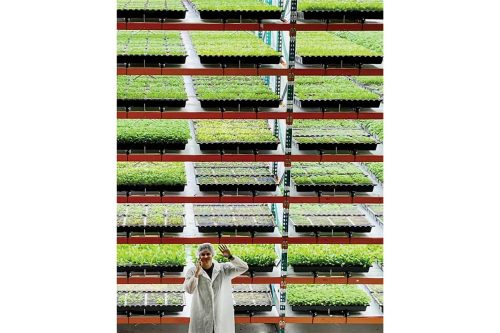

As an indoor vertical farm, Beanstalk grows crops in rows of shallow trays to allow for more efficient use of the facility’s dimensions. To do so, the Ross brothers use a system they designed known as a “growing tower.” The nine-level, 100-foot-wide, 24-foot-deep apparatus, which CEO Mike Ross calls “the world’s largest vending machine,” operates vertically and horizontally to lower plants from the stacked shelves for workers to harvest, package, and deliver. The farm currently operates one tower, but they plan to add two more.

The operation is 200 times more productive than traditional farms. Beanstalk can grow more than 100 acres worth of produce on just a half-acre of land while using 90 percent less water.

The idea did not sprout overnight. The brothers trace the roots of Beanstalk Farms to 2017, when Jack, now 28, was an undergraduate student at the University of Virginia. There, he was awarded a $5,000 grant that afforded the duo the materials to build their first growing tower prototype. By 2018, they were opening a 3,000-square-foot farm in Springfield, which closed when they moved to Herndon.

The Ross brothers are now hoping to see their growing method employed elsewhere.

“Nutritious, fresh produce is hard to find, so we eventually want to take our show on the road,” Mike Ross says. It’s an endeavor that will be enhanced by their emphasis on sustainability. Because Beanstalk is an indoor farm, it does not rely on changing seasons and uses no pesticides or chemicals, Ross says. Beanstalk also uses clean, tested tap water, which is recycled along with composted plant waste and soil.

It’s a completely closed-loop system that results in Beanstalk producing zero waste and being carbon-neutral.

A Farm of the Future

Imagine a fully automated farm. A farm that doesn’t need pesticides or have “seasons”. A farm that helps the environment by recycling water and reducing carbon emissions. Beanstalk is building farms that support our future.

Grows Seeds from Around the World

Beanstalk’s indoor farms create

the perfect environment for the tastiest seeds from around the world. Local produce can now be exotic.

Within the City

To build our farms, we refurbish commercial buildings with our vertical gardens. Our new growing system is 100x more productive so we can bring the farm into the city.